You are here:

Technology for painting, laser marking, and pad printing

Mastering every single painting, laser marking, pad printing, and hot stamping stage and obtaining the best quality possible even for complex items

Technologies

Technology for painting, laser marking, and pad printing

Mastering automation

Mastering the techniques of every single stage and obtaining the best quality possible even for complex items. Manual processes, yet valuable, are not suitable for large-scale productions. The latter can be repeated over time and be enriched with top-quality aesthetic details.

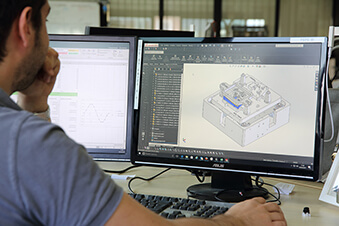

Technology allows Seristudio to take care of every single stage, thanks to IT systems designed in-house.

The result is a perfect co-operation between artisan tradition and technical design carried out by qualified mechanical and chemical engineers.

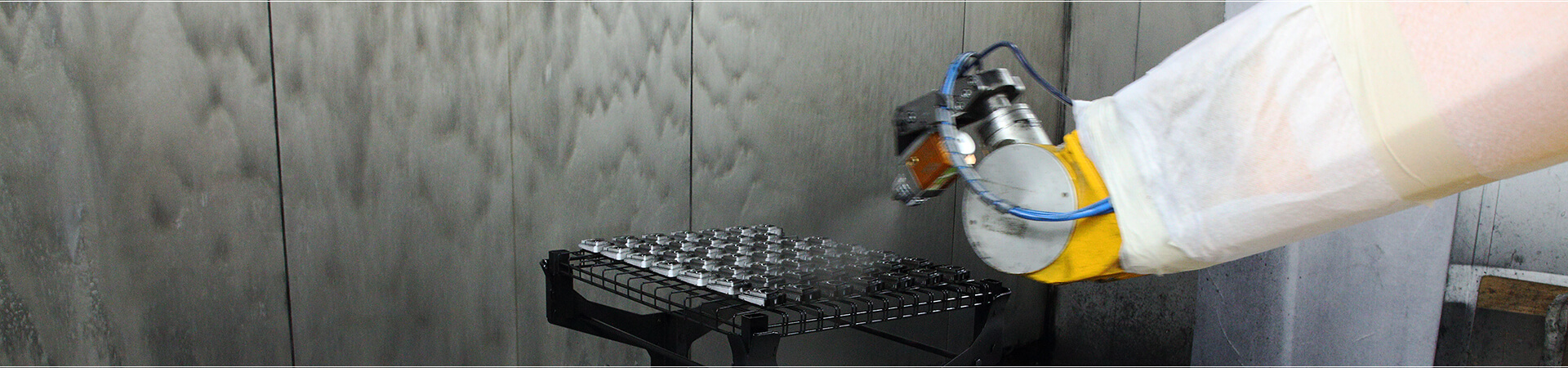

This is what allows Seristudio to create complex items. Items that can be obtained by automated procedures, such as laser marking.

So, the high automation level the company has reached over time has allowed Seristudio to produce over 35 million painted items per year.

Technology blends with our 30+ years of experience in the treatment of decorated items, even small ones, with various techniques, such as pad printing or hot stamping.

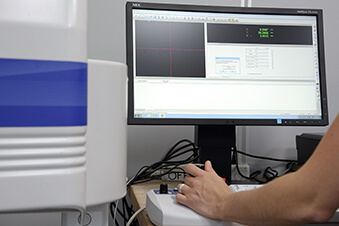

High quality means optimising processes in the pursuit of efficiency. Efficiency that can be achieved through continuous updates and training on machinery.

The technological know-how has allowed the company to overcome the main difficulty these processes imply, meaning the distribution of a liquid paint with a constant thickness on a curved surface with a variable radius.

In fact, only Seristudio's automated processes and work cycles designed for every item (over 800 different items and over 200 production cycles) and automatic control systems can make sure the high-quality standards required by vehicle regulations.

All processes are monitored through high-performance control equipment. Moreover, our know-how has allowed Seristudio to develop a high engineering level that ensures high production rates.

Today, the company boasts:

ENGLISH

ENGLISH  ITALIAN

ITALIAN FRENCH

FRENCH GERMAN

GERMAN