You are here:

Plastic injection molding and mold construction

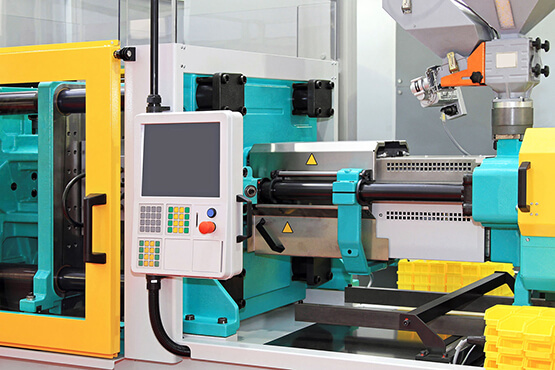

Next-generation presses for the best quality ever for injection molding of plastic and plastic materials and the construction of molds and prototypes

Molding

Plastic injection molding and mold construction

Next-generation presses for the best quality ever

Plastics molding processes are transformation technologies used to create components made of polymeric materials by means of a mold.

Seristudio specializes in the injection molding of plastic materials, as well as in the construction of molds and prototypes.

The company started its activities focusing on top-quality technical parts, which helped Seristudio gain extensive experience in this kind of components.

The company's consolidated experience has allowed Seristudio to develop an SPC (Statistical Process Control) program, now on the market, in collaboration with a first-rate Software House.

Seristudio creates its molds in its tooling department, which controls the timing and quality of the molds. This is an excellent support for the special maintenance of the molds being series production.

The molding of high-precision technical parts increases Seristudio's competitiveness on the market. The company's machine fleet is now made up of 22 presses weighing from 25 to 250 tons.

All the presses are equipped with the following:

Moreover, this department is also equipped with 7 machines for automatic screen printing of the parts.

ENGLISH

ENGLISH  ITALIAN

ITALIAN FRENCH

FRENCH GERMAN

GERMAN